The Heart of Flow Control: Exploring Valve Types and Functions

Introduction

In the world of fluid mechanics and engineering, the role of valves is

nothing short of remarkable. These unassuming devices are the unsung heroes

of countless processes and systems, responsible for controlling the flow of

liquids, gases, and even solids in a precise and efficient manner. Valves

are the gatekeepers of flow control, and understanding their types and

functions is crucial for engineers, designers, and anyone interested in the

mechanics of fluid movement. In this comprehensive exploration, we delve

into the heart of flow control to uncover the diverse world of valve types

and their essential functions.

The Basics of Valves

Valves are mechanical devices designed to regulate, direct, or stop the flow

of a fluid or gas within a system. They accomplish this by opening, closing,

or partially obstructing a passageway or pipe. Valves play a pivotal role in

industries ranging from oil and gas to water treatment, and their design and

function can vary significantly to suit specific applications.

Gate Valves: Controlling the Flow

Gate valves are one of the most common types of valves, known for their

straightforward design and effective flow control. These valves feature a

flat, gate-like disc that is raised or lowered to control the flow of fluid.

When the gate is fully raised, the valve is fully open, allowing for

unrestricted flow. Conversely, when the gate is lowered, the valve closes

off the flow completely. Gate valves are commonly used in applications where

on-off control is required, such as in water distribution systems and fire

protection.

Globe Valves: Precision in Flow Control

Globe valves are aptly named for their spherical body shape. They are

characterized by a movable plug or disc that is positioned against the flow,

regulating it with a linear motion. Unlike gate valves, globe valves provide

precise control of flow rate by allowing for adjustments at various

positions between fully open and fully closed. This makes them suitable for

applications requiring fine-tuned control, such as steam systems and HVAC

(Heating, Ventilation, and Air Conditioning) systems.

Ball Valves: Versatile and Efficient

Ball valves are known for their simplicity and reliability. These valves

employ a rotating ball with a bore through it to control the flow of fluid.

When the ball is turned 90 degrees, it aligns with the pipe, allowing for

full flow, and when turned perpendicular to the pipe, it blocks the flow

entirely. Ball valves are versatile and find application in industries

ranging from petrochemicals to pharmaceuticals due to their ease of use,

durability, and minimal leakage characteristics.

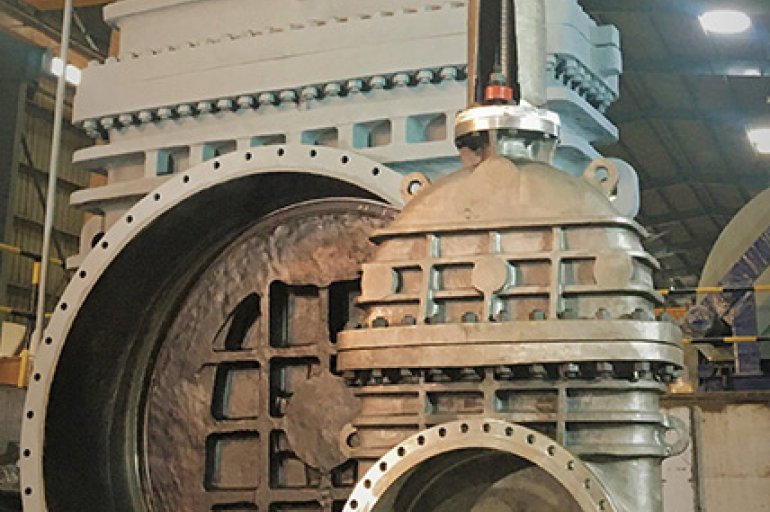

Butterfly Valves: Streamlined Flow Control

Butterfly valves are designed for quick and efficient flow control. These

valves feature a flat disc or "butterfly" that is mounted on a spindle. By

rotating the disc a quarter turn (90 degrees), it can be aligned either

parallel to the flow for full flow or perpendicular to block the flow.

Butterfly valves are often used in large pipelines for their low-pressure

drop and quick operation. They are commonly found in water treatment, HVAC

systems, and the food industry.

Check Valves: Preventing Backflow

Check valves serve a critical role in preventing backflow in pipelines.

Unlike other valves that control flow in both directions, check valves are

unidirectional, allowing flow in one direction while automatically

preventing flow in the opposite direction. These valves are essential in

systems where backflow could cause contamination or damage, such as sewage

systems, heating systems, and pumping stations.

Pressure Relief Valves: Safety in Overpressure

Pressure relief valves, also known as safety valves, are designed to protect

equipment and systems from overpressure conditions. When the pressure in a

system exceeds the preset limit, these valves automatically open to release

excess pressure and prevent potential disasters. Pressure relief valves are

found in various applications, including steam boilers, pressure vessels,

and pipelines carrying hazardous materials.

Solenoid Valves: Electromagnetic Precision

Solenoid valves are a type of electromechanical valve that relies on an

electromagnetic coil to control the flow of fluid. When an electrical

current is applied to the coil, it generates a magnetic field that moves a

plunger or a diaphragm to open or close the valve. Solenoid valves are

commonly used in automation and remote control systems, making them ideal

for applications like irrigation systems, vending machines, and industrial

machinery.

Diaphragm Valves: Containment and Isolation

Diaphragm valves are unique in their design, featuring a flexible diaphragm

or membrane that isolates the fluid from the valve body. When the diaphragm

is compressed or relaxed, it controls the flow of the fluid. Diaphragm

valves are particularly useful in applications that require a high level of

containment and purity, such as pharmaceutical manufacturing and chemical

processing.

Plug Valves: Simplicity and Reliability

Plug valves are known for their simple yet effective design. These valves

use a cylindrical or tapered plug with a hole through it to control the

flow. By rotating the plug, the flow can be opened or closed. Plug valves are

versatile and can handle a wide range of fluids, making them suitable for

industries like oil and gas, wastewater treatment, and petrochemicals.

Choosing the Right Valve for the Job

Selecting the right valve for a specific application is crucial for ensuring

optimal performance and efficiency. Factors to consider when choosing a

valve include the type of fluid, temperature, pressure, flow rate, and the

level of control required. Additionally, material compatibility and

environmental conditions should be taken into account.

Conclusion

In the world of engineering, the devil may be in the details, but the heart

is in the valves. These remarkable devices, from gate valves to solenoid

valves, play an indispensable role in regulating the flow of fluids and

gases across a multitude of industries and applications. Whether it's the

precision of globe valves or the simplicity of ball valves, these

gatekeepers of flow control ensure the smooth and efficient operation of

countless processes and systems.

For those seeking high-quality valves to meet their specific needs, look no

further than Oswal Industries Limited. As a leading valve manufacturer and

supplier in India and across the globe, Oswal Industries Limited has

established a reputation for excellence and reliability. Their commitment to

innovation, quality, and customer satisfaction has made them a trusted

partner for industries spanning from oil and gas to water treatment, and

beyond.

In the intricate world of fluid control, where precision, safety, and

efficiency are paramount, Oswal Industries Limited stands as a beacon of

expertise. With their comprehensive range of valves and unwavering

dedication to excellence, they continue to be at the forefront of flow

control solutions, ensuring that the heart of every system beats with

precision and reliability.