Oswal’s manufacturing plant spreads over 110000 SQMT of land in Gujarat, India.

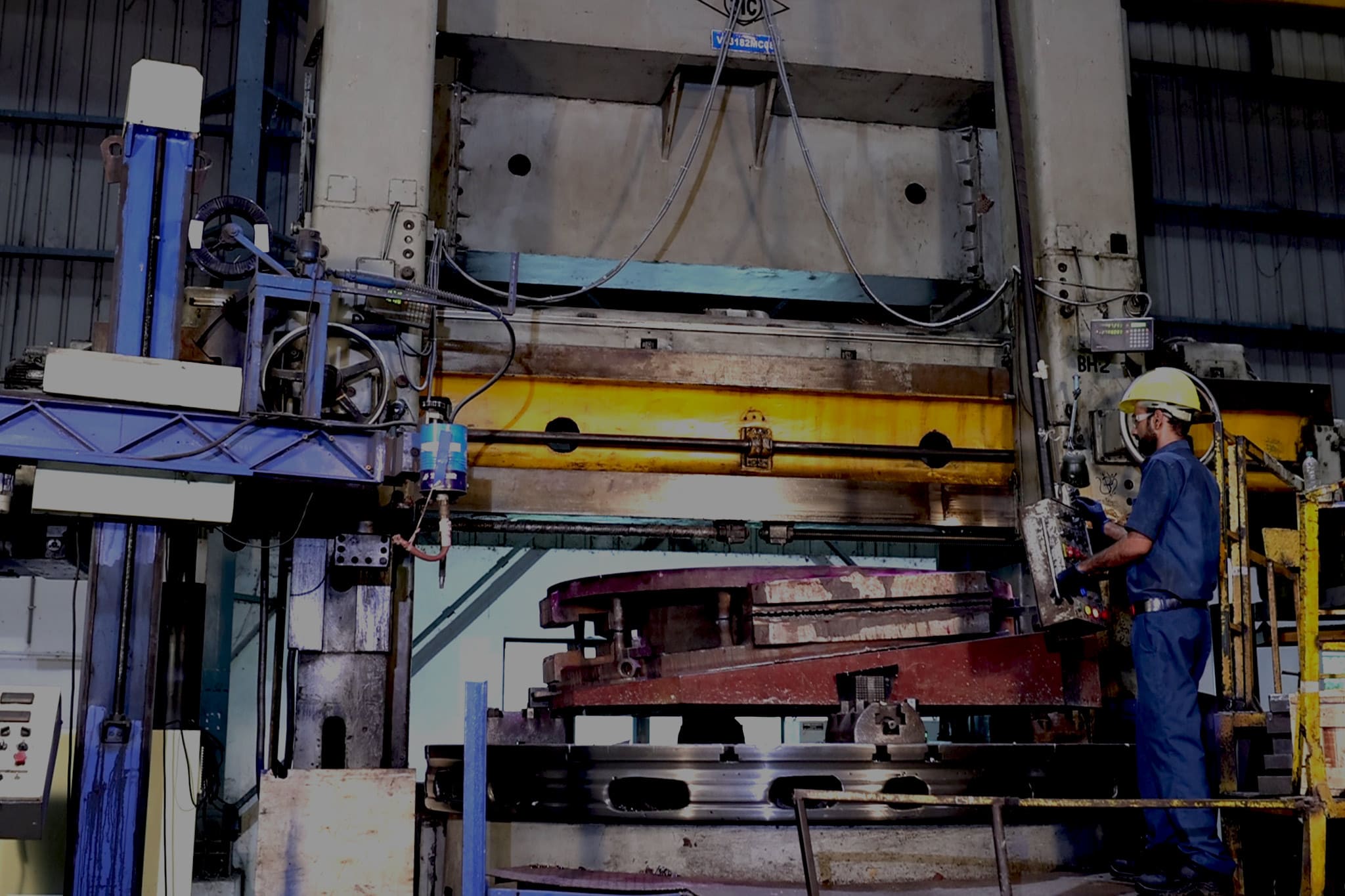

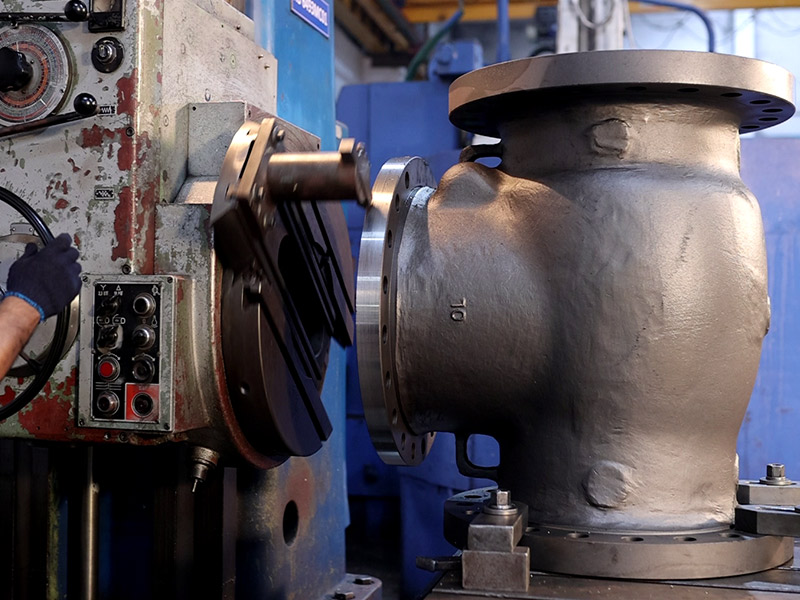

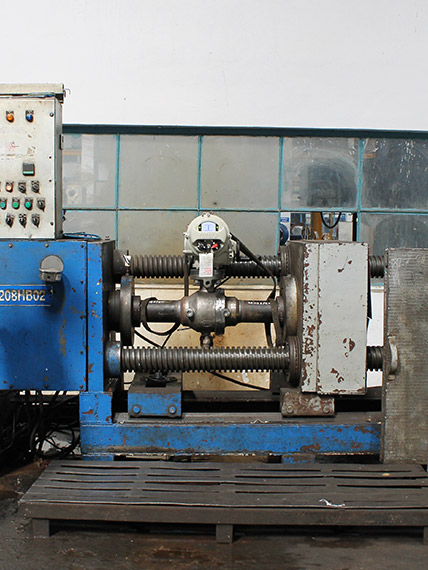

Largest single location integrated facility for Valves and Foundry products. Plant is operating with state-of-the-art manufacturing facilities such as IOT enabled Machin-shops, 5-axis Trevisan Machining Centre, CNC Vertical Turret Lathes, CNC Horizontal Machining Centers, Special Purpose Machines, Automated Welding Machines, Automated painting facility, Multiple Cranes with 20 ton capacity etc.,

Oswal facility is certified for API 600, API 6D, CE, NORSOK M650 etc., in addition to various other domestic and international approvals

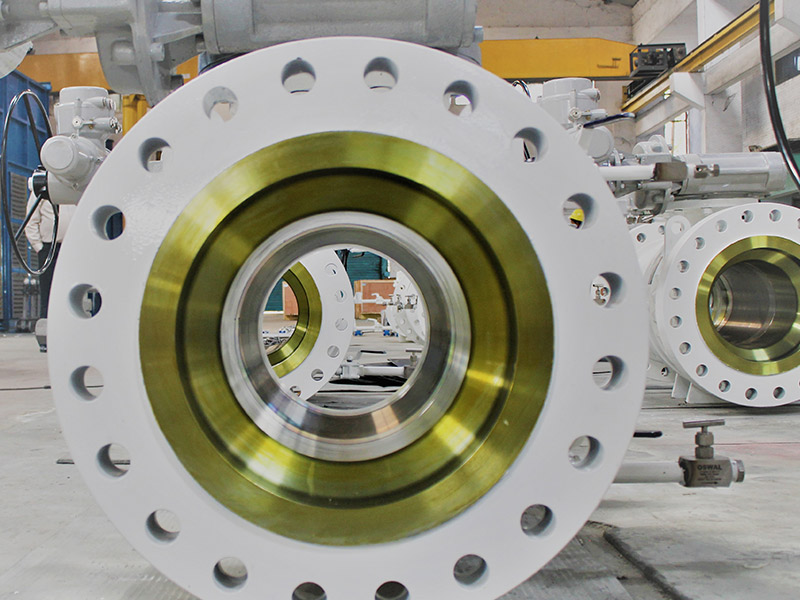

Oswal has the capabilities to manufacture wide range of valves in different materials including alloy steel, stainless steel, nickel alloys, duplex and super duplex stainless steel etc. Over 3 decades, Oswal has been consistent in manufacturing high quality products.

Process and Systems are integrated through ERP which is resulting consistent throughput enabling timely deliveries to customers. With inhouse captive foundry, robust systems, Oswal is widely known for FastTrack orders meeting shorter delivery to cater customers’ emergency and shutdown requirements.

Capacity of manufacturing is as high as 100000 valves per annum for Gate, Globe, Check and Ball valves. Oswal is also a well-known quality manufacturer of Cryogenic, Oxygen, Hydrogen and various special services and customized valves.

Entire team is trained and dedicated with project management skills and works with paramount objective of customer satisfaction.