Check Valves

The check valve is a type of direction control valve as it is primarily used to control the direction of the fluid flowing inside the pipe. It is a unidirectional valve that allows liquid to flow in only one direction.

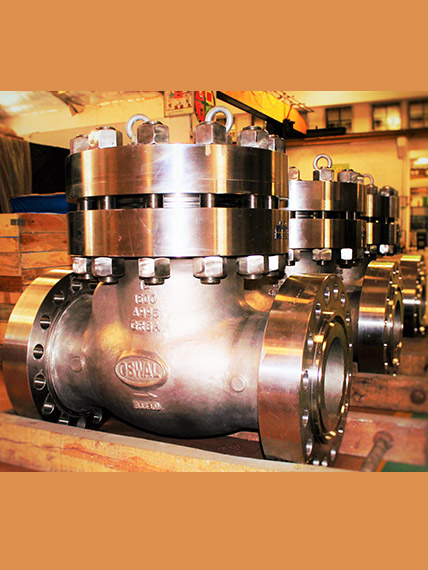

A manufacturer of high-quality check valves at reasonable prices, Oswal Industries produces high-quality check valves.

Oswal Industries is one of the world's leading check valve manufacturers and suppliers. There won’t be any compromise in terms of quality because our check valve sellers only sell certified valves for a better customer experience. Check valves are activated by line fluid pressure and closed by gravity. The back pressure of lime fluid also facilitates sealing. The components of check valves include the body, cover plate, disc, body seats, nuts, stud bolts, gasket, etc. All these components are put together to form a full-fledged check valve. Check valves are also known as non-return valves as the direction of the working fluid is unidirectional as mentioned. It does not allow the working fluid to flow in the other direction. Get the highest quality check valves from the top check valve manufacturer. We entertain our clients not only at the time of their purchase from us but also after that. We make sure that you are provided with the highest quality services for as long as you need them.