The Ultimate Guide to Cryogenic Valves

Are you someone who is looking to get some information on cryogenic valves? Also, do you want to know the world’s leading cryogenic valve manufacturers that manufacture them? If yes, then this blog is everything that you need to get well-versed with cryogenic valves. This blog aims to provide information on The Ultimate Guide to Cryogenic Valves. Where are they used? What is the best place to buy a cryogenic valve? So let’s start without wasting any more minutes!!

What is a Cryogenic Valve?

Cryogenic valves are one of the most critical valves used in various industries worldwide for low-temperature applications. A cryogenic valve is unique in handling low-temperature applications in the piping system. Low-temperature gases like oxygen, hydrogen, nitrogen, etc. are categorized under cryogenic gases which include Liquid Natural gas (LNG) and Compressed natural gas (CNG). The cryogenic valves are also meant for high-pressure applications which further adds to the criticality. Cryogenic valves are effective in providing the sealing as per applicable testing standards. You can rely on these valves without any problem because these are very well manufactured and tested by keeping in view all the safety measures.

Why can standard valves not withstand what cryogenic valves can?

Besides applicable “product standard” compliances, Cryogenic valves are governed by BS 6364 / ISO 28921 standards to qualify for meeting the critical requirements. The standard valve cannot handle extremely low temperatures which might lead to an unavoidable situation. Find the best cryogenic calves from the cryogenic suppliers in India that meet your requirements and expectations positively.

Valve types such as Gate, Globe, Check, Ball Butterfly, etc are being used for Cryogenic applications.

Cryogenic ball valves generally have a higher flow rate than globe valves. These are very much effective where tight sealing is required but it should also be kept in view that these valves are prone to deterioration in the areas that are tightly sealed. Valves are available in various class ratings right from class 150. Besides major input raw materials, soft packing and O rings that are used also must be taken with additional care to meet the challenging low temperatures.

Where can you get the best cryogenic valves?

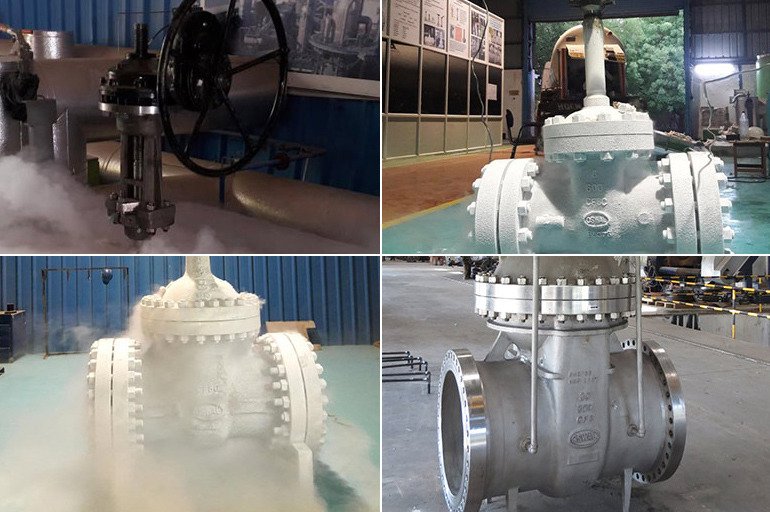

There are plenty of cryogenic manufacturers and suppliers available in India and one of the leading organizations is “Oswal” valves. These cryogenic valves are manufactured under the best technical practices and fully complying the respective standards applicable. They are capable of supplying larger valves too as they have In-house cryogenic tanks for testing.

Valves are suitable for -196 degrees Celsius temperature. Cryogenic valves can comply with fugitive emission requirements. These valves are manufactured and tested as per BS 6364/ ISO 28921. SIL 3 certification is also possible. Cryogenic valves also can be supplied with a suitable actuation system.

Also, the services that they offer are impeccable. They have customers around the corner and are known as one of the leading quality manufacturers of cryogenic valves. They are very competitive for both price and delivery with their in-house foundry which can provide exotic material required for low-temperature applications.

Conclusion

Cryogenic valves come under the critical application category and you can buy from quality manufacturers like Oswal, the world’s leading manufacturer and supplier of cryogenic valves.