Valves in the Oil & Gas Industry: Overcoming Challenges & Enhancing Safety

The oil and gas industry plays a pivotal role in driving the global economy. However, this industry is also fraught with challenges that range from complex operational processes to environmental concerns. One critical component that stands at the heart of oil and gas operations is the valve. Valves are not just mechanical devices; they are the guardians of safety and efficiency in this high-risk industry. In this blog, we'll delve into the challenges faced by valves in the oil and gas sector and explore how advancements are enhancing safety.

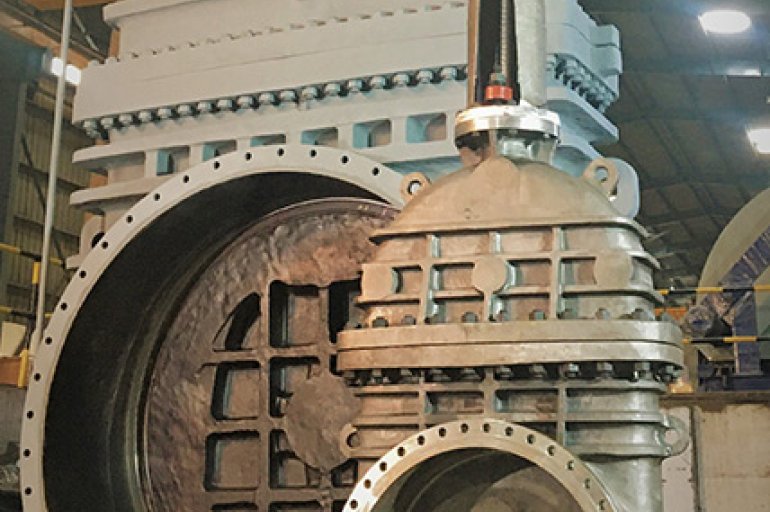

The Crucial Role of Valves

Valves hold an irreplaceable position within any oil and gas operation. They

regulate the flow of fluids and gases, facilitating effective production,

seamless transportation, and refining processes. Throughout various

stages—be it extraction, pipeline transport, refining, or

distribution—valves are essential. They come in diverse types, including

gate valves, ball valves, globe valves, and butterfly valves, each tailored

for specific functions.

Challenges in the Oil & Gas Industry

Operating within the oil and gas sector means confronting unforgiving

conditions that challenge equipment integrity and operational efficacy.

Valves, in particular, face unique challenges:

1. Rigorous Environments: Oil and gas facilities are often situated in

remote and severe settings, from offshore platforms to arid deserts and icy

Arctic regions. Valves must withstand extreme temperatures, corrosive

substances, and high pressures while maintaining optimal efficiency.

2. High-Pressure Conditions: High-pressure scenarios are the norm in the oil

and gas sector. Valves must be designed to endure these conditions while

ensuring impeccable seals to avert leakages and prevent hazardous

blowouts.

3. Corrosion and Erosion: The fluids processed in this sector can be

corrosive, leading to gradual material deterioration within valves.

Furthermore, the ceaseless flow of abrasive materials results in erosion,

jeopardizing valve integrity and potentially causing malfunctions and leaks.

4. Safety Imperatives: Safety takes precedence within the oil and gas

industry. Valve malfunctions can trigger gas leaks, fires, explosions, and

environmental catastrophes. Guaranteeing the dependability and fail-safe

operation of valves is paramount to avert such incidents.

Advancing Safety Through Innovation

Despite these challenges, the oil and gas sector remains at the forefront of

embracing innovations that augment valve performance and overall safety:

1. Material Progress: Manufacturers are forging ahead with new materials

that boast excellent resistance to corrosion and erosion. Advanced alloys and

coatings extend the lifespan of valves and reduce maintenance needs,

fostering safer and more efficient operations.

2. Smart Valve Technology: Incorporating sensors and monitoring systems into

valves has revolutionized the industry. These intelligent valves can detect

shifts in pressure, temperature, and flow in real time, empowering operators

to identify potential issues before they escalate into emergencies.

3. Remote Monitoring and Control: With the rise of the Industrial Internet

of Things (IIoT), valves can now be remotely observed and controlled. This

capability diminishes the necessity for personnel to be physically present

in hazardous environments, thereby minimizing exposure to potential hazards.

4. Predictive Maintenance: AI-driven predictive maintenance tools analyze

data from valves and other equipment to forecast maintenance requirements.

This proactive approach precludes unforeseen valve failures, curtails

downtime, and amplifies safety by pinpointing potential issues before they

trigger accidents.

5. Emergency Shutdown Systems: Valves are integrated into emergency shutdown

systems that automatically close valves in response to critical conditions.

This swift response can forestall or mitigate disasters, shielding

personnel, equipment, and the environment.

The Future Landscape of Valves in Oil & Gas

As the oil and gas industry marches forward, valves will remain linchpins

of safety and operational excellence. Anticipated advancements may include:

1. Nanotechnology: Researchers are probing the application of nanomaterials

to fabricate valves with heightened resistance to corrosion, erosion, and

wear. Nanotechnology could potentially reshape valve design, rendering them

even more robust and dependable.

2. Hybrid Valves: By amalgamating the strengths of various valve types, the

industry could unveil hybrid valves that proffer enhanced performance and

versatility across diverse conditions.

3. Automation and AI: Infusing artificial intelligence into valve control

systems could facilitate autonomous responses to changing conditions,

further mitigating accident risks and enhancing operational efficiency.

Conclusion

Valves play an essential role in the oil and gas sector, acting as guardians

of safety and efficiency in a challenging industry. Overcoming the hurdles

posed by harsh environments, high pressures, and safety concerns requires

constant innovation and dedication. The oil and gas industry has made

significant strides in enhancing valve performance and safety, driven by

advancements like smart valve technology, remote monitoring, and predictive

maintenance.

In this journey of progress, companies like Oswal Industries Limited,

prominent valve manufacturers and suppliers in India, have been at the

forefront of pushing the boundaries of valve technology. Their commitment to

excellence has contributed to the development of materials, designs, and

technologies that are better equipped to withstand the demanding conditions

of the oil and gas industry. Such proactive engagement by companies like

Oswal Industries Limited ensures that valves continue to evolve as

resilient, reliable, and crucial components in ensuring the safety and

efficiency of oil and gas operations.

Looking ahead, the future of valves in the oil and gas industry holds the

promise of even greater advancements. As technology evolves and new

materials are explored, valves are likely to become even more durable,

efficient, and adaptable to changing conditions. With the integration of

artificial intelligence, hybrid valve designs, and ongoing collaboration

between industry leaders and researchers, the oil and gas sector will

continue to enhance its safety measures while optimizing operational

processes.

In conclusion, valves are the unsung heroes of the oil and gas industry,

ensuring the secure and efficient flow of energy resources. Through

innovation, collaboration, and the unwavering dedication of manufacturers

and suppliers like Oswal Industries Limited, prominent valves manufacturers

and supplier in India, the industry is poised to meet challenges head-on

and maintain its commitment to safety and sustainability in the years to

come.